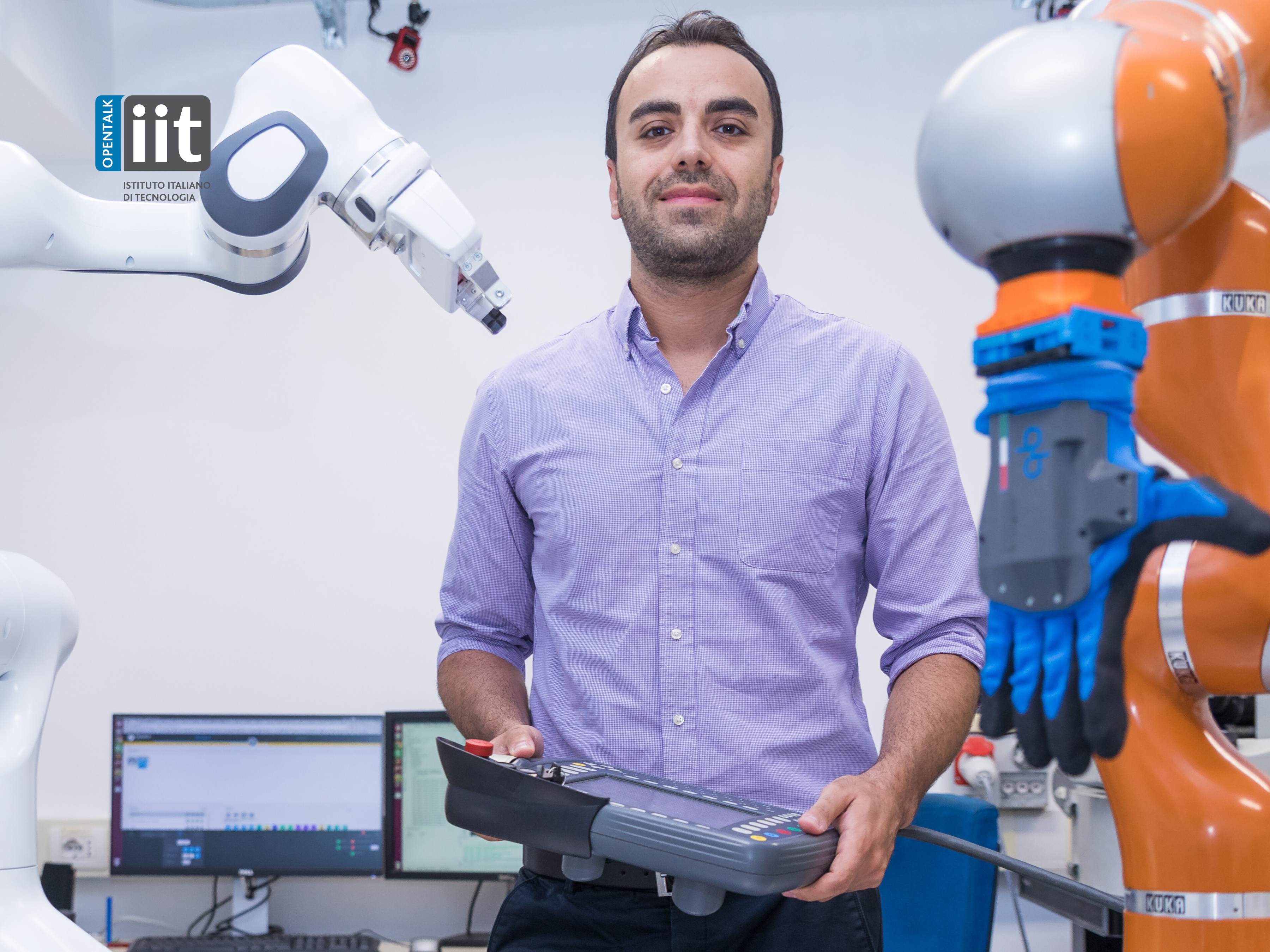

Interview with Arash Ajoudani, leader of the Human-Robot Interfaces and physical Interaction Lab in IIT

Over the last years you were awarded with several international awards because of the research you are conducting in the field of collaborative robotics; you participated in competitions organized by large companies such as Kuka and Amazon. Today you coordinate an European project, called Sophia, involving industries that are interested in improving their production lines, such as Volkswagen. Thus, can we affirm that collaborative robots will be adopted by factories soon?

Smart collaborative robots are the inevitable components of the factories of the future. This is because, today, there is a trend towards mass customization. The response to this requirement has been through manual operations and traditional automation tools. However, collaborative robots that work alongside humans can add high flexibility to the industrial processes while offloading human workers from strain and repetitive tasks. In such a way, factory resources will be better organized, which will ensure cost-effective productivity and quality, while minimizing waste. When it comes to small and medium enterprises (SMEs), the role of collaborative robots becomes even more crucial. According to a study by the European Commission, SMEs represent 99 % of all businesses in the EU, where their dynamically changing environments can largely benefit from flexible collaborative robots for prosperity. Therefore, all arrows are pointing to the need for the creation of smart collaborative robots to ensure their wide and cross-application integration in industry.

The association of the words “robot” and “job” together, for some people means “loss of employment”. In the case of collaborative robotics this is not true, indeed the goal is to make the workplace healthier. Can you explain how it will be possible?

Human workers are the most valuable asset of every company. This is because of their creativity, dexterity, and problem solving skills, which will always outperform those of the robots. However, robots can brings other benefit to the hybrid production systems “humans plus robots”. They can perform repetitive tasks, carry heavy loads, perform monotonous transportation of objects and tools, and in general, improve the ergonomics of the workplace. It is estimated that, work-related musculoskeletal disorders that are caused by non-healthy working conditions, each year cost 240 Billion Euros to European Union. Collaborative robots can certainly contribute to a reduction of such expense by making the workplace more healthy and productive.

Nowadays there is an open discussion about the use of robotics in emergency scenario such as that of the pandemic we are experiencing. Some years ago, it was the nuclear accident in Fukushima that made the international community thinking about acting and developing robots able to help humans. How far robotic technologies have advanced and what can we do with the robots available today?

If you think about the definition of pandemic, that is an epidemic of disease that has spread across a large region, for instance several continents, or worldwide, then you can consider different scenario. In this sense, work-related musculoskeletal disorders, as the single-largest category of work-related diseases, are in fact, an undervalued pandemic. These diseases have affected frontline industrial workers’ health, and contributed to a significant economic loss worldwide. Hence, from one hand, collaborative robots will improve human ergonomics and reduce negative consequences of physical labour. On the other hand, since collaborative robots will work alongside humans, they can also help with social distancing, in situations such as the recent Corona virus outbreak, with a minimum impact on the overall productivity. Note that, robots can be easily disinfected and re-used on a daily basis, to help human workers in their daily tasks.

Besides, there is another interesting aspect: the modularity and fast deployment capacity of the collaborative robots. For instance, in SOPHIA project that I am coordinating, we aim to develop modules that can be potentially re-used in teleoperation control of robots for patients’ reception and testing. For instance, a robot, which is teleoperated by a nurse, can do the tampon test for Corona virus exam, without a direct human contact, hence minimizing the virus’ spread.

Your research activity is supported by the European Union, in particular also by European Research Council grant. Of course this is an important economic support, but does it represent anything else for you?

Indeed, European Union’s research frameworks such ERC or H2020 provide excellent opportunities to respond to the societal and technological challenges that emerge in our complex societies. Moreover, the collaborative nature of such programs also encourage knowledge and data sharing among EU experts, which permits us to implement an effective and minimum-waste approach towards resolving real-world problems.