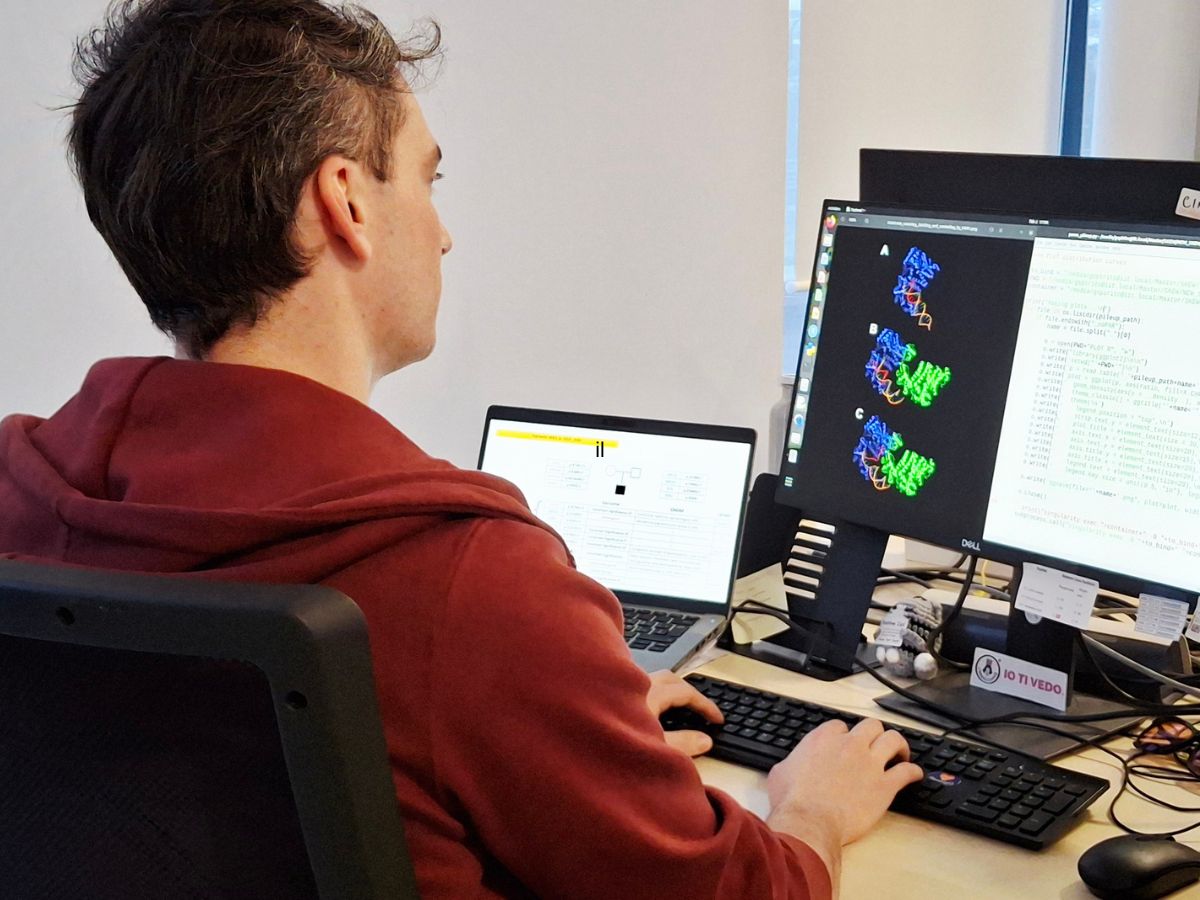

Interview with Michele Tamagnone, coordinator of IIT’s Nanophotonic Devices Lab

Today we need to transmit huge amounts of information, quickly and over great distances. Thanks to an ERC Starting Grant, Michele Tamagnone – the first researcher in the Nanophotonic Devices research line at IIT’s Centre for Convergent Technologies – is leading the SubNanoOptoDevices project, for the realisation of nanostructures based on two-dimensional materials. This would make it possible to create miniaturised and ultra-fast devices to significantly increase the effectiveness of telecommunications.

The project is dedicated to the development of miniaturised photonic and optoelectronic devices. What are they and how are they realised?

We speak of ‘low dimensional materials’, mainly two-dimensional. Among 2D materials, the most famous is graphene, but there are many others, such as boron nitride. These materials already have some very interesting properties in themselves, but one of the most interesting things that has emerged in recent years is the possibility of using them to make optical modulators: these are devices in which you take the material, place it near a waveguide (where light passes through) and then apply an electrical signal to it. The material is then able to change from a state in which it is completely transparent (light passes through it) to a state in which it absorbs some light; with a sufficient propagation length, it is then possible to make a switch, in which the electrical signal is transformed into an optical signal.

What can be the use of such a switch?

This is typically used for telecommunications. Nowadays we need to transport increasing amounts of data. But the bottleneck is not so much the optical fibres where the data passes: what still limits us are these optoelectronic devices, which serve as a bridge between the world of electrical signals (that of computers) and the world of optical signals (that of optical fibres). So there is this sort of middle world between optics and electronics, namely optoelectronics, which is an important building block for being able to communicate over large distances. This need has generated a lot of interest in creating new optoelectronic devices, which are getting smaller and smaller with specially engineered materials. There are also attempts to integrate them directly on the silicon with the electronic part. Today, a modulator is a fairly large device (a few centimetres in size); the aim is to miniaturise it, so that several of them fit on the same silicon chip.

What is the point of miniaturising a device?

At the moment, we are in the same situation as we were a few decades ago with computers: at that time, very bulky and low-speed computers were made. Miniaturisation is always the key to greater speed and, in this case, greater communication capacity. At the moment, these devices are bulky and limit many applications. Having a chip with several very small devices allows us to have many channels of information. On an optical fibre, it is possible to transport a large amount of information, but optoelectronic devices must be miniaturised to exploit this capacity.

The problem mentioned is what motivates so much research in the field of optoelectronics. But specifically, what is the aim of this research?

I mentioned earlier that 2D materials are very interesting because it is possible to change their optical properties by applying an electrical voltage. By applying an electrical voltage, you can ‘inject’ electrons. Once these electrons are inside the material, they interact with the photons and change the properties of the material. However, there is a problem with this method: injecting electrons takes a relatively long time (although we are talking nanoseconds). There is a major limit to the speed this switch can have. The idea is therefore to make the switch even faster, so that it can turn light on and off with the highest possible frequency and thus transmit more information. To speed up the process, we propose a completely different system, in which we do not change the number of electrons inside the material, but we change the ‘band structure’ of the material: that is, we create an electrical potential that disrupts the behaviour of the electrons; this allows us to have a material with different properties.

How is this achieved?

Instead of putting the 2D material on a silicon chip, we put it on a special substrate consisting of two oxides (aluminia and hafnia), which are insulators. In other words, we develop a technology that creates such substrates, in which the two oxides, which are smaller than 2 nanometres, alternate. On this substrate we place the 2D material and, by applying a voltage, instead of injecting electrons (which is a slow process), we cause an oscillating electric field to be created in space. This allows the properties of the material to be changed on a nanoscale, where they are governed by quantum mechanics. If this concept works, it could have huge implications, because it would allow us to make a material that can absorb and emit light very efficiently at the frequencies we want.

What are the wavelengths at which you want the material to absorb/emit light?

Typically, some materials can only absorb or emit visible light, but telecommunications on fibre usually take place in the infrared. So the idea is to make the material absorb in the infrared instead of the visible. In my research I mainly focus on the absorption part.

Why is it necessary to alternate between two oxides? Wouldn’t it work using a substrate uniformly composed of only one oxide?

No, because we would not change the band structure of the material. What we want is to create a faster process than injecting electrons. With just one oxide, applying an electric voltage would create a uniform electric field in space and the process would be slow. To speed up the process, we need to create an electric field that changes in space and this can be done by applying an electric voltage to alternating layers of two oxides. For this to work, they must be very small variations (on the order of 2 or 3 nanometres) and therefore have an electric field that oscillates within the radius of those 2 or 3 nanometres. This is impossible with normal manufacturing processes, because then we would be able to have structures of 10 nanometres.

What stage is your research at?

We are in the first step, whose project still consists of basic research, where we observe the phenomena we have been talking about: we are still talking about applied physics, not device engineering. Once we have verified the resistance of these oxides to high voltages, we place 2D material on top and perform optical measurements. When this step is demonstrated and we can observe these phenomena, the next step is to create the device (step two) and prove that the modulator made will work. To create an actual product will take several years, given the complexity of the research. But the goal is to demonstrate, at the end of the five-year project, the functionality of the process.

Are there other studies parallel to yours that aim to engineer 2D materials for these purposes?

One of the hottest topics these days involving 2D materials are structures called moiré patterns, which are two 2D materials placed on top of each other in a slightly rotated manner.This in itself already creates periodic structures in space, which should have the same function as our two oxides.But they can’t compete with what we propose, because they have too weak an effect and also they only work at very low temperatures.In our case we operate at room temperature, otherwise there would be no point in talking about practical devices.

This is a complex research, but one that may yield nice surprises along the way.

We may realize, for example, that this type of device can also function as an emitter, such as a laser or an LED.