Interview with Sergio Dulio, Head of Research & Innovation Business unit Atomlab

The ATOM Group, of which the ATOMLab Innovation division is a part, is active in the design and production of machinery and process systems for the manufacture of footwear and leather goods. The headquarters are in Vigevano, in the province of Pavia, but the group is structured over five production units (including two in China) and 10 branches all over the world. They make different families of products, from numerical control cutting machines to plastic sole injection systems, to a wide range of machinery for footwear assembly. Recently they have studied highly automated robotic solutions that are now entering the market. They also have a division that develops highly appreciated software for 3D parametric footwear design. The work group in Italy employs around 300 people and in 2018 (latest data available) achieved a turnover of just over 100 million euros.

Mr. Dulio, the appearance of coronavirus in China was the first sign of problems for your business. Could such a dramatic development have been predicted?

We first heard the news about the virus emergency from our production unit in China, which is located in the Shanghai area. After the break for the Chinese New Year holidays, the factory, like many others in that country, was unable to resume its operations until another three weeks later. The emergency seemed to be under control, and confined to that continent. We certainly didn’t expect it to reach us, and hit use so aggressively.

Your operations gradually stopped. What is the situation like now?

After the declaration of the first “red zones”, our company had already implemented organisational changes by adopting a smart working model for all the technical (design and innovation departments) and administrative departments, keeping production operational. Following the adoption of the lockdown nationwide, production activity was also reduced to a minimum. Nevertheless, we have continued to operate by supplying cutting machinery to many companies engaged in the production of personal protective equipment (masks).

We are all waiting for operations to resume, which will hopefully be soon. What are the corrective measures to be taken to resume work safely?

Although the legal provisions are not very clear, we have already adapted to the new safety indications in recent days to allow the necessary staff to carry out the reduced operations I mentioned earlier, to work safely. Now we are preparing for complete recovery (hopefully soon) by adopting all the measures provided for by the directives: minimum staff spacing, body temperature measurement, use of gloves and masks, reorganisation of work shifts, the systemic organisation of working from home. We are confident that we can recover safely for our workers, our suppliers and our customers as soon as the state allows us to.

What is your assessment of the reaction of the markets after coronavirus?

It is still too early for a precise analysis, also because the various production areas of the footwear world have entered into crisis asynchronously; the Far East has already started up again and machinery orders have largely been maintained, albeit with a few exceptions. We also expect a contraction because with the drop in demand on the consumption front it is foreseeable that production in those countries will also drop. For other production areas, especially in Europe, the situation is different; there are signs of the maintenance of the initial investment plans, especially on certain types such as automation, but it will take some time to understand if these signs will consolidate.

Do you think that behind some of the rigidity towards our country by some representatives of the European Community there is an attempt to undermine Made in Italy brands?

Personally I am not convinced; I don’t think it is attempts by this or that country to undermine the competitive advantage of our companies. Rather, I think that Europe, and the world in general, still have to realise that this global crisis requires a global responses, the development of a sense of solidarity that is still partially lacking and the awareness that to return to prosperity we need to work together. Perhaps a somewhat idealistic vision, but at this stage I think it is extremely necessary.

This forced stop is allowing us to re-evaluate many relationships and initiatives cancelled previously by a frenetic system. Among the activities that are proposed is training. Can you tell us about your initiative organised in this area?

In fact, this long period of reflection has allowed us to focus on priorities and issues that found no place in the frenetic pace of life before. Training, both individually and collectively and organised, is one of them. This was one of the ways in which business continuity was maintained with my innovation team. Personally I am convinced that this will be an area in which we will have to concentrate energy and attention, also in relation to the transformations that this crisis will induce in the world of work with the advent of new professions and the transformation of old ones. A commitment to which I am dedicating a good part of my professional and private time; and this includes the complementary distance learning project I am working on together with the Piacenza and Vigevano bank foundation (which is its sponsor and financier) and the Rotary Club Vigevano Mortara. Our intent is to provide primary and secondary school children with a vast training, socialisation and intellectual entertainment programme with the aim of giving them support and purpose in this period in which socialisation and regular commitment are lacking in the classroom. In this regard, I am grateful for the support that the Italian Institute of Technology has declared itself ready to give us on the topic of robotics and as part of a high-level pathway based around Industry 4.0.

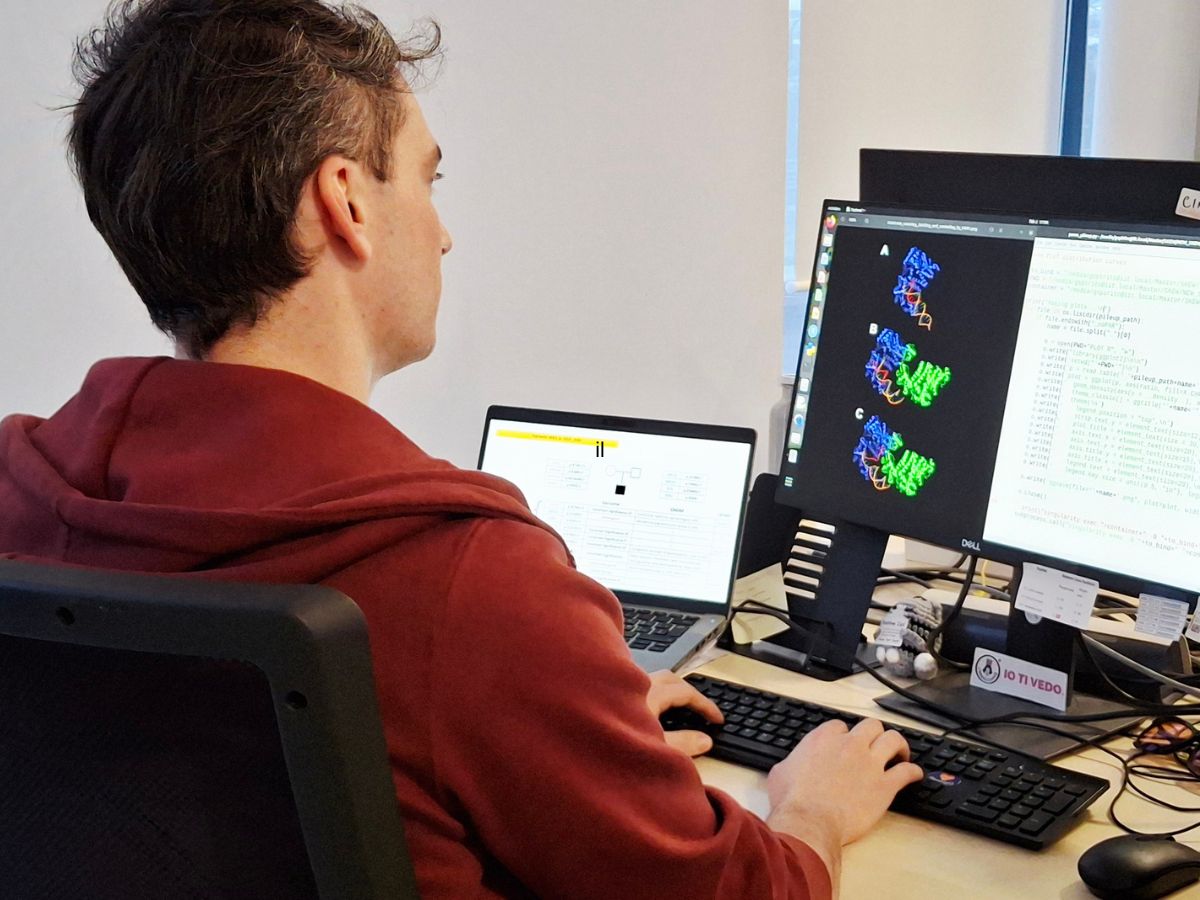

In your company, the use of new technologies is widespread – why and what have the results been like? Do you think that in the future this extremely innovative vision can be increased?

Our company has long been engaged in the development of machinery and systems that incorporate various advanced technologies: from vision to robotics, more recently to augmented reality. We also started the first explorations in the field of Artificial Intelligence and Machine Learning to understand their applicability to the shoe production processes. We are convinced that we can meet a growing demand from our customers with this and at the same time we are also incorporating some of these technologies directly into our production processes. In light of the transformations that the emergency we are experiencing will bring, we are convinced that the push towards innovation can only increase.