The prototype is the result of the European project “Concert” coordinated by the IIT in Italy. It was tested at an actual construction site in Poland

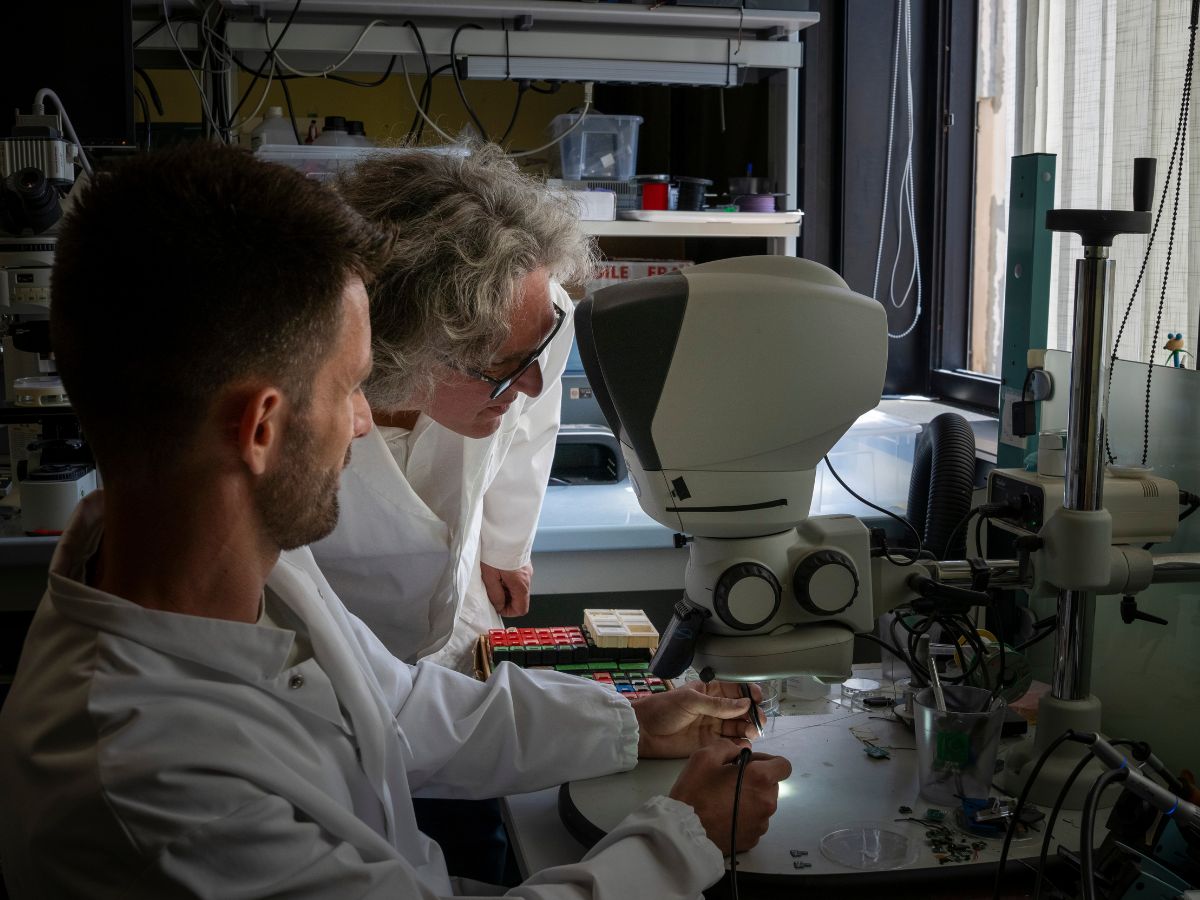

The CONCERT robot is ready to assist workers with high-risk tasks at construction sites. This innovative prototype was designed and developed at the Istituto Italiano di Tecnologia (IIT – Italian Institute of Technology) as part of the EU-funded CONCERT project, which concluded after three years of activities and real-world scenario testing. The robot can perform tasks that require high physical effort or are particularly harmful to workers’ physical health, such as drilling at height, spraying of insulation material over large surfaces, and loading and transporting heavy items such as formwork elements.

The CONCERT project was funded by the European Union with a grant of 3 million euros Coordinated by Nikolaos Tsagarakis, a researcher at IIT, the project involved companies and research centers from Italy, Germany, Austria, and Poland.

Two research teams from IIT participated in the project: the Humanoid & Human Centered Mechatronics team, led by Tsagarakis, and the Human-Robot Interfaces and Physical Interaction Lab, led by Arash Ajoudani. Both groups are key players in the development of innovative cobots.

The research consortium also included the Polish construction company Budimex, which provided the use case scenarios and hosted the real-world testing of the robotic platform in their construction site.

The construction sector ranks among the most hazardous workplaces in reports published by INAIL, both for the frequency of serious accidents and for the number of lives lost each year. Workers are required to perform intense physical labor, work at height, or apply substances like insulation, paints and plasters. The use of robots to assist humans in these and other tasks can therefore help reduce the risk of injury and make construction sites safer.

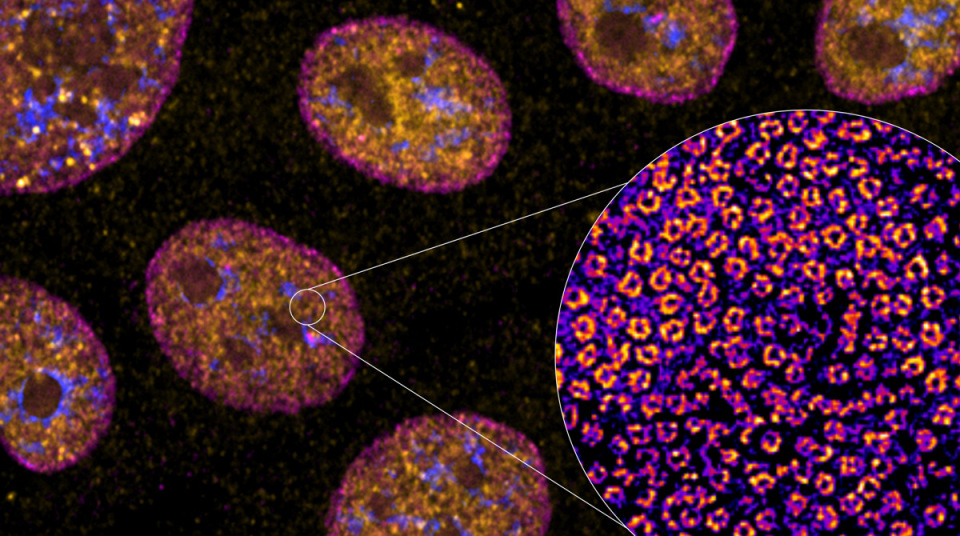

The CONCERT robot is a fully modular and reconfigurable mobile manipulator, representing a world-wide state of art robot. The body of CONCERT robot is composed by a number of modules that can be quickly interconnected together in various arrangements, enabling to realize different robot embodiments, which provide enhanced onsite flexibility and interoperability.

Its sensors and interfaces allow it to interact with the external environment and collaborate efficiently with humans, adapting to challenges such as confined spaces, heights, and obstacles. Thanks to these features, the robot can reduce some of the physical strain and repetitive tasks typical of construction sites, positively impacting workers’ health and safety.

The platform consists of a mobile base with wheels and a robotic arm system for manipulation, both modular and configurable. It has a compact form with dimensions of 1m x 0.7m, which, along with its maneuverability, allows the CONCERT robot to navigate and pass through narrow spaces or areas blocked by obstacles, requiring precise steering capabilities.

The manipulation system consists of several modules of joints, links, and end-efectors equipped with working tools, ranging from a drill to a spraying and sanding tools. The modular manipulator can reach a height of over 3 meters, thus preventing workers from having to use ladders or scaffolding to perform drilling, spraying and sanding operations. The different modules can perform tasks with high payload requirements, exceeding 20 kg, depending on their configuration.

The total weight of CONCERT is 150 kg, and it can carry a payload of over 200 kg on its mobile base, acting as an autonomous transport platform in construction sites or other work environments.

In addition to its reconfiguration ability, the robot is equipped with sensors that allows it to interact with the external environment and cooperate with humans, including Lidar and 3D cameras, ultrasonic sensors, and force/contact sensors, enabling the robot to perceive its surroundings, detect human presence, and identify interactions with them.

Field tests in real construction sites have demonstrated the capabilities of CONCERT: navigating within a construction environment, successfully performing tasks ranging from drilling walls to painting and sanding, as well as collaborating with construction workers in equipment assembly operations. The research team is ready to collaborate with new companies to further validate the robotic platform and meet the health and safety needs of work environments.

The CONCERT project, funded under the grant agreement No 101016007 of the Horizon 2020 research and innovation programme, is the result of collaboration between the Istituto Italiano di Tecnologia in Genoa, Fraunhofer Italia in Bolzano, Technische Universität München in Germany, Profactor GmbH in Austria, CIOP-BIP, and Budimex in Poland.