The European project is coordinated by the Istituto Italiano di Tecnologia, involves 12 partners across Europe, and will run for four years

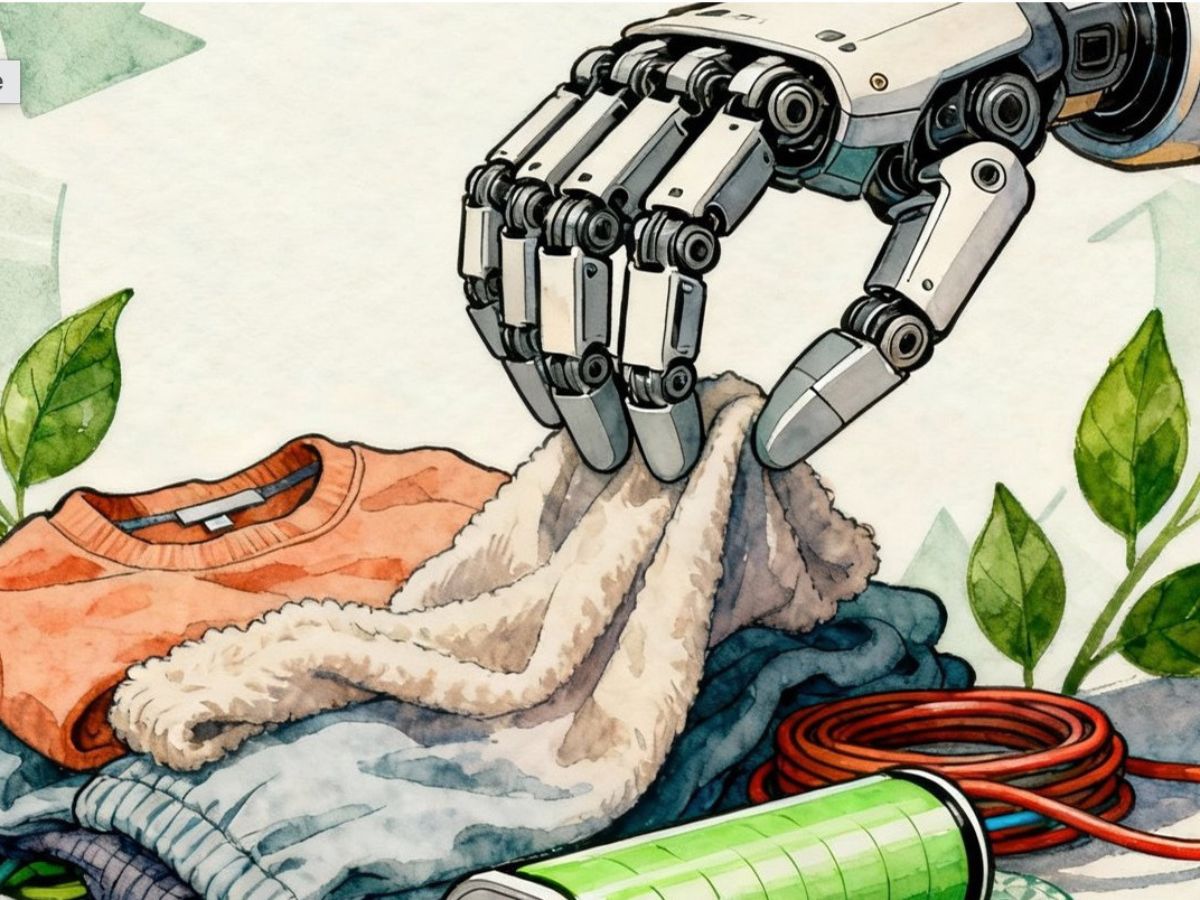

FlexCycle is a new European project coordinated by the Istituto Italiano di Tecnologia (IIT) that aims to advance robotics and artificial intelligence technologies to make the lifecycle of industrial products more sustainable. The project focuses in particular on the reuse of materials that remain difficult to process, especially flexible ones. Researchers will develop autonomous systems capable of manipulating flexible materials and structures—such as those found in garments, electrical cables, and batteries—to disassemble a wide range of products and recover reusable components. Bringing together 12 partners, including universities and companies from six European countries, FlexCycle has secured €7.5 million in funding over the next four years.

The project is coordinated by Manuel G. Catalano, Principal Investigator at the Istituto Italiano di Tecnologia and head of the new research unit “NuBots, Physical AI Technologies for Human-Robot CoEvolution” in Genoa. He also coordinates the joint systemic laboratory JOiiNT Lab, established through the public-private IIT-Intellimech initiative and based in Bergamo.

Electronic devices at the end of their life cycle, along with spent batteries and discarded textiles, pose a significant environmental and economic challenge for the European Union, accounting for millions of tons of waste each year. Addressing this issue requires the development of innovative technological solutions that can enhance existing waste management processes within a circular economy framework. Although robotics has already been successfully applied to the handling of rigid objects, managing flexible and deformable materials remains a largely unresolved challenge.

The FlexCycle project—short for “Flexible Robotic Automation Techniques for Soft Materials Recycling”—will target three key industrial sectors in which robotics can support the integration of flexible, AI-driven systems for handling non-rigid components.

The first is the clothing industry, where the goal is to recover fabrics and accessories such as buttons and zippers from unsold garments. The second is the production of electrical cables, in which valuable materials like copper and other metals can be reclaimed only after removing the insulating sheaths that encase them. The third focuses on the recycling of fuel-cell batteries, through the extraction of the soft membranes of fuel cells, which are immersed in toxic substances. In this case, the objective of recovering and reusing the membranes will also inform the design of a new generation of fuel cells.

For each case, the consortium will identify and define the specific challenges to be addressed, with the aim of developing complementary technologies that, when integrated, can tackle the issues unique to each application context. The research team will investigate the scientific challenges involved in manipulating flexible materials and determine the most suitable technological solutions for their recovery and disposal. Throughout the project, research institutions will collaborate closely with industry partners to ensure a strong alignment between scientific advances and the practical needs of different industrial environments.

The intelligent robotic technologies will be designed to be reliable and robust, and to be flexibly combined and adapted to different scenarios. Manipulation technologies will be crucial: IIT researchers, together with QBRobotics, will develop new specifications for the Soft Hand—an originally IIT-invented soft robotic hand that has already been applied in archaeology, including underwater and field operations at the Archaeological Park of Pompeii, as well as in prosthetics and industrial settings. In addition, other innovative grippers will be employed, such as the SoftClaw, also based on soft robotics principles, but designed to perform high-precision tasks with a high degree of adaptability. New specialized tools will be studied and integrated to enhance grasping capability and flexibility across different use cases.

From a software perspective, artificial intelligence technologies will need to identify different objects, recognize their geometry and specific features, and understand the various processing steps required. For example, in the case of garments, systems may need to detect the type of stitching securing a zipper in order to remove it correctly. In cable processing, they will have to navigate tangled wires, isolate the target cable, and separate the successive layers of insulating and conductive materials.

“Soft materials are present in many consumer products,” explains Manuel Catalano, IIT researcher and coordinator of the FlexCycle project. “However, recycling solutions specialized for a single product group, such as textiles, are usually rigid and not easily adaptable, and cannot be applied to other sectors, such as cables. Our project addresses this issue by developing flexible automation methods that can be rapidly and efficiently transferred across different industrial sectors.”

The project consortium consists of: Istituto Italiano di Tecnologia (IIT) as coordinator; Institut Jožef Stefan (Slovenia); Georg-August-Universität Göttingen (Germany); Consejo Superior de Investigaciones Científicas (CSIC) (Spain); Technische Universität München (Germany); Fraunhofer-Gesellschaft (Germany); Vytautas Magnus University (Lithuania); qbrobotics (Italy); Electrocycling GmbH (Germany); Symbio (France); OSIT Impresa SpA (Italy); and Cablex (Slovenia).