A new electrostatic actuator technology, developed by three Italian research centres, the Sant’Anna School, the University of Trento and the Italian Institute of Technology, transforms vacuum from an operational limitation to a functional resource

The vacuum, which has always been considered one of the most hostile components for mechanical systems, becomes a key resource for space robotics thanks to a new technology of electrostatic actuators developed in a study published in the journal Nature Communications.

The research, coordinated by the Institute of Mechanical Intelligence at the Sant’Anna School of Advanced Studies in Pisa, in collaboration with the University of Trento and the Italian Institute of Technology (IIT), opens up new perspectives in the design of more efficient, reliable and economical space robots.

The limitations of traditional electric motors in space

In the context of space missions, traditional electric motors – the “muscles” that allow robots to move – present significant challenges: overheating in the absence of atmosphere, the need for special lubricants, high complexity and weight. These factors have a significant impact on the cost, reliability and performance of robotic systems operating in space.

The vacuum as an ally of movement

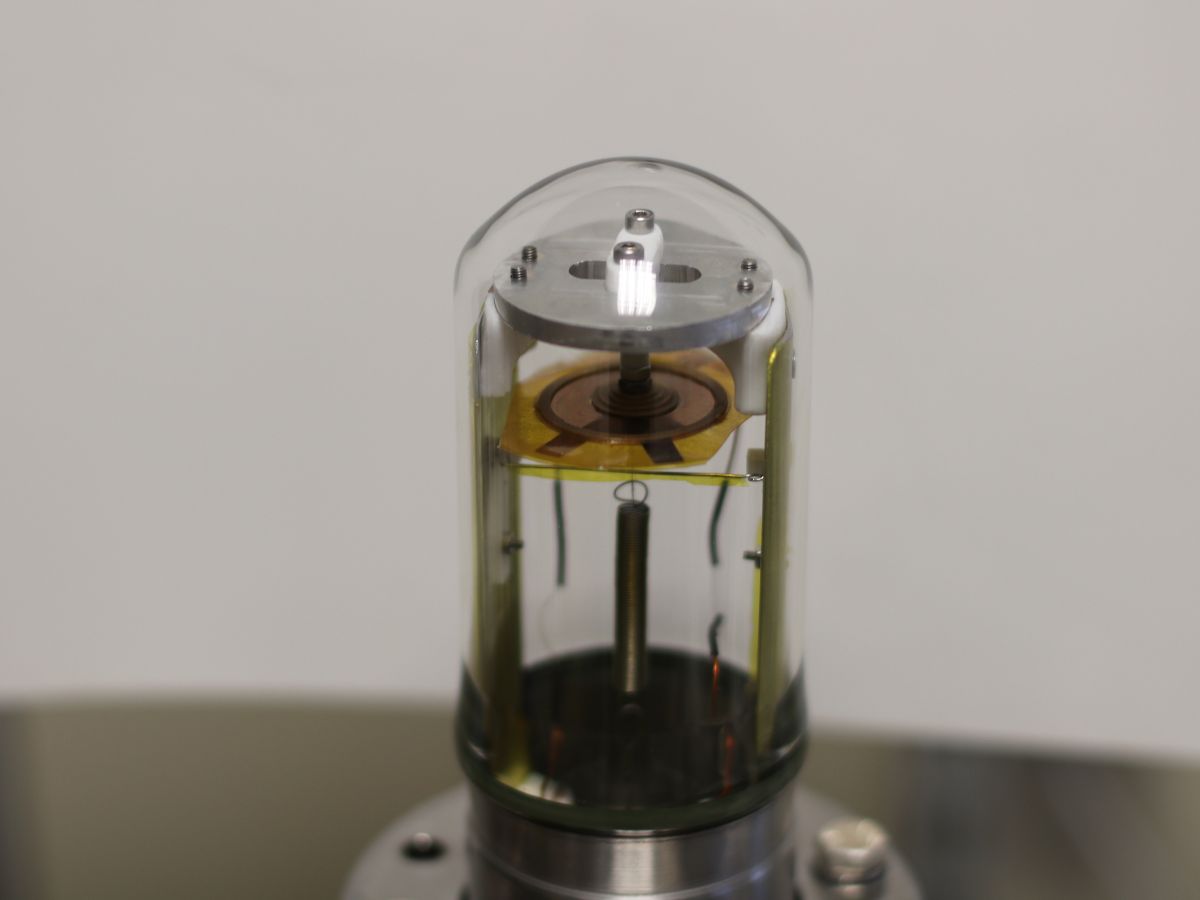

The study proposes a new class of extremely light and simple electrostatic actuators that exploit the electrical properties of the vacuum. In this way, what has historically been one of the main difficulties for mechanical systems in space becomes a key element in the functioning of the actuators.

The devices developed are gearless and lubricant-free and are perfectly compatible with the materials and standards already used in space missions. Initial experimental results have demonstrated the ability to generate rapid movements and significant forces, with a very high power-to-weight ratio and greatly reduced energy consumption, which are crucial aspects for use in orbit and exploration missions.

“We have identified a solution that demonstrates how the vacuum, which has always been considered a critical environment for robotics, can become an ally in creating lighter, more efficient and reliable systems for future missions” says Ion-Dan Sirbu, first author of the study.

Potential applications

The technology has broad and significant application prospects: robots for maintenance and assembly in orbit, systems for planetary exploration, and mobile mechanisms for satellites and space telescopes. In the long term, the approach could also be extended to terrestrial contexts characterised by extreme conditions, such as the ocean floor or highly critical industrial environments.

Statements

“The low weight of our actuators is a determining factor in space applications, where every additional kilogram significantly affects the cost of launching into orbit” comments Marco Fontana, professor at the Institute of Mechanical Intelligence at the Sant’Anna School and coordinator of the study.

“The absence of air allows our actuator to reach very high speeds, eliminating losses due to friction” says Giacomo Moretti, associate professor at the Department of Industrial Engineering at the University of Trento.

“A key element in the development of these devices lies in the manufacturing process, based on the deposition of thin flexible insulating films, which allows the device to operate reliably” explains Virgilio Mattoli, researcher at the Centre for Materials Interfaces at the Italian Institute of Technology.